|

|||

|

|

|

||

| View Shopping Cart |

| Home |

| Guides Available |

| About the Author |

| FAQs |

| Testimonials |

| Articles |

| Contact Andrew |

| Terms & Conditions |

| Mailing List |

| Links |

|

|

Gibbs Guides.com

More high quality articles and information absolutely

free with every

Gibbs Guides newsletter. Sign up now!

Skyship

The story of a large RC flying saucer

Part 2- Final assembly and flight testing

By John Gibbs

Gas bags

Another task was to source a suitable material for the gas bags. The material

had to be lightweight, possess good helium retention and be easily joined.

However, the helium molecule is very small, and consequently it has the

ability to pass through almost any material, albeit at a limited rate.

Some research was therefore needed to find a suitable material from which

the gas bags could be made. After some effort a plastic film was found,

which met these requirements reasonably well. I believe it came from the

USA.

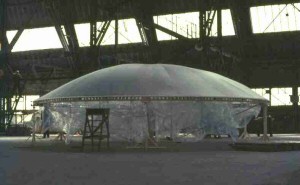

Test assembly

Once the construction had been completed, the parts were test assembled

in a large hall. Fortunately, there were no problems.

|

Time to move

We now had what amounted to a 10 m diameter ARTF airship, so the next

stage of the project was to assemble, finish and test fly the model Skyship.

Clearly, both tasks had to be carried out indoors. Permission had been

obtained to use one of the old airship sheds at Cardington, Bedfordshire

for this purpose. The journey to Cardington must have been unique in that

our van was stuffed absolutely full yet our cargo weighed only a few pounds

in total!

The enormous airship sheds

at Cardington, winter 1974. Each of the two sheds is 812 feet (248m)

long, 180 feet (55m) wide and 157 feet (48m) tall. The doors are

so large that they run on a length of rail. |

A view of the interior of

the Cardington airship shed. What look like barrage balloons can

be seen, although I never found out what these were used for. Skyship

can be seen on the right hand side of the picture, looking rather

alien in comparison with the balloons! |

Skyship’s covering was

held in place around the ring beam by studs at intervals. The covers

were made from white spinnaker fabric, if memory serves me correctly. |

Making the gas bags

The gas bags were made in situ, once the structure of the machine had

been assembled. The welding of the plastic film was really tedious and

difficult. Very careful heat control was necessary and meticulous care

had to be taken to prevent any future helium gas leakage. They were also

very large items with many meters of jointing required.

Un-inflated gas bags can be

seen here below the cover. The lifting gas used to fill them was

a mixture of helium and hydrogen. This was less expensive than pure

helium and a little more buoyant. |

Power and control systems

Skyship's power system consisted of four electric motors each about the

size of a Speed 700. These were nominally rated at around 200 Watts, and

were fitted with white nylon Keil Kraft 12 x 4 propellers. Small 6V lead

acid motorcycle batteries were used for a power source. These may seem

a strange choice for an airship, but at this time suitable nickel cadmium

types were not yet available.

A specially adapted Flight Link multi-channel proportional radio control system was used to control the airship. The receiver was connected to a large aluminium box containing a number of relays for motor speed control. Probably this meant that motor control was of the off/half/full speed variety, either forwards or backwards. The four electric motors were evenly spaced around the ring beam’s periphery. These could be vectored using the RC servos. Thus, the motors could be used to provide full directional control.

Time to fly

Eventually everything was ready for the flying trials. The bags were filled

with lifting gas and with great relief it was found that the weight calculations

were correct and neutral buoyancy was achieved. The gas bags were nearly,

but not completely gas tight. An ingeniously simple system was devised

by my colleague to provide compensation for the continuous small loss

of lift caused by the inevitable leakage of helium. This was a container

of water with a small hole that allowed water to drip out at a suitable

rate.

The buoyant model airship.

The propellers are just visible at the right hand edge of the ring

beam. I was very surprised by how small they were in comparison

with the overall size of the model, but they did provide sufficient

thrust. Several 6V motor cycle batteries provided the power source

– possibly just two. The brown item in the foreground is a

gas cylinder. |

My wife and our two children

came up to Cardington as they were all very interested in the project.

For reasons unknown, the name Skyship was positioned upside down

at this stage, although this was later corrected. |

The team standing beneath

the buoyant model. The airship’s designer and pilot, Robin

Wren is seen crouching, holding the modified Flight Link transmitter. |

Alas, the flying trials were not particularly successful. The model could not be controlled as well as had been hoped. Too late we realised that the fluorescent lighting in the Cardington shed was probably interfering with the radio control, at one time causing the airship to rise far too high. We were displeased when the “Telegraph” published unflattering remarks about control of the craft, especially as their own reporter had caused the model to nose-dive by treading on a restraint line!

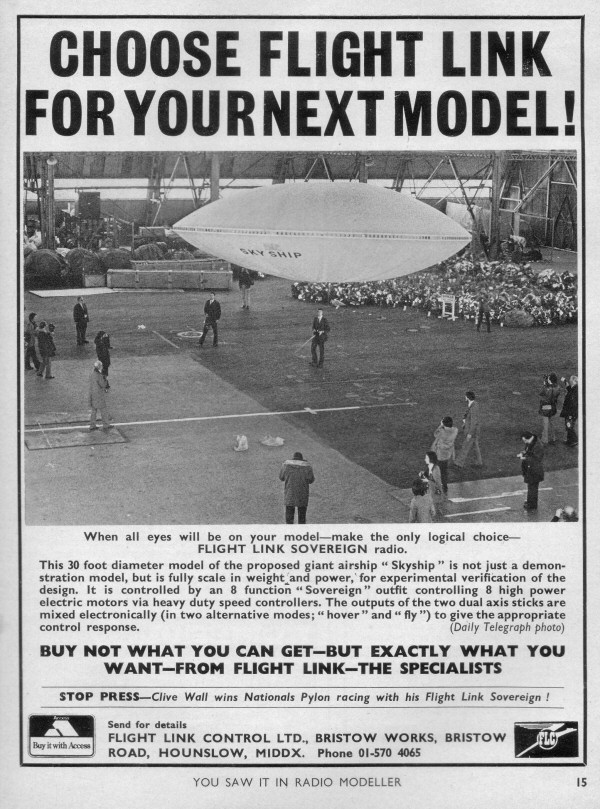

Flight Link, the manufacturer

of the custom-built radio control system used in Skyship ran this

advert in the July 1975 edition of Radio Modeller. The system was

an 8-channel system controlling the 8 electric motors via heavy-duty

speed controllers. The outputs of the two dual axis transmitter

sticks were mixed electronically (in two modes; 'hover' and 'fly')

to give the appropriate control response. |

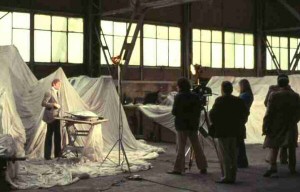

The BBC TV programme “Tomorrow’s

World” became interested in the project. The table model is

seen here standing on a disguised workmate bench in front of presenter

William Woollard. My colleague told me later that he had introduced

an entirely fictitious “visiostatic balance bag” in

discussions with the “Tomorrows World” interviewer.

Much to our amusement mention of this item was duly included in

the broadcast! |

Much was learned from the flying model, but sadly its

fate is not known. By 1976 the company had become named Airship Developments

and the design of a new airship, the AD500 was taking shape on its drawing

board. One machine, G-BECE was produced and this became the prototype

for the successful Skyship 500 series of airships produced by Airship

Industries. Although these were of a traditional shape, they did incorporate

a pair of vectored, ducted fans for thrust and control. So, at least one

design detail from the original table model design concept made it all

the way to a production airship.

Much was learned from the

Skyship models. |